News & Insights

Protecting marine life through Woodfibre LNG’s innovative marine mammal monitoring program

Dec 19, 2024

Marine mammals rely on sound for navigation, communication, and locating food. Underwater noise generated by industrial activities can interfere with these functions, causing changes in behaviour and disrupting the natural habits of marine life. To ensure that the Project’s in-water work minimizes underwater noise, Woodfibre LNG uses a series of proven technologies, monitoring practices, and best practices that lower the amount of underwater noise and helps marine life continue as normal throughout Howe Sound.

This programming is one of the most robust on a major industrial project and is another way that Woodfibre LNG goes beyond industry standards to uphold environmental stewardship, in cooperation with the Sḵwx̱wú7mesh Úxwumixw (Squamish Nation). Through requirements under Woodfibre LNG’s Federal Decision Statement and its Environmental Assessment Certificate, the Marine Mammal Monitoring and Mitigation Plan was co-developed and approved by the Squamish Nation to protect marine mammals.

Learn more about the different components of the marine mammal monitoring program below.

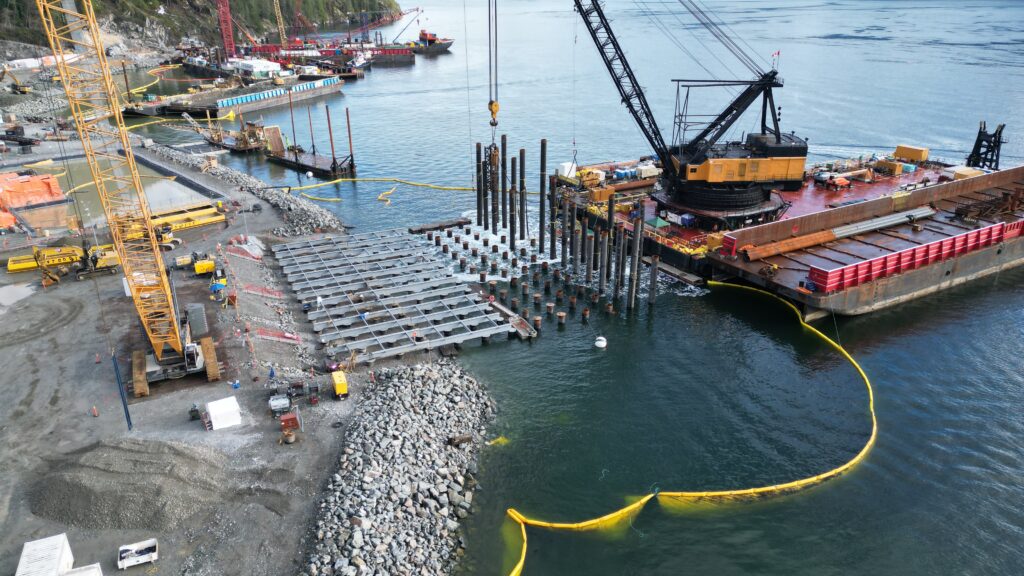

Bubble Curtains

Bubble curtains create a physical barrier of air bubbles that helps absorb sound waves, reducing noise levels in surrounding waters. By releasing compressed air through perforated hoses or dedicated nozzles, a wall of rising bubbles is placed around a noise source. These “curtains” effectively reduce noise generated by pile driving and other construction activities, which can have significant sound impact if not mitigated. Sound waves hit the bubble curtain where the energy is absorbed and scattered, drastically reducing noise intensity and how far construction noise will travel underwater.

Vibratory Pile driving

Marine structures, like the moorings required for the floatel or the project’s floating storage, are supported by series of piles – long steel cylindrical beams that transfer weight or stress from structures above water into the seabed below, anchoring it firmly in place.

In many construction settings, piles are driven using impact piling which relies on high impact strikes to the pile, similar to a hammer driving a nail. When installing marine piles, Woodfibre LNG seeks to use vibratory piling over traditional impact piling whenever possible. Unlike impact piling, which generates loud, sudden impulsive noise, vibratory piling uses steady continuous vibration to reduce friction with the soil and drive piles into the seabed. A vibratory hammer is attached to the top of the pile and generates rapid, vertical vibrations that travel down the pile, loosening the soil around it. These vibrations temporarily reduce the earth’s resistance, sinking the pile to into the ground with less force, less noise and no sudden percussive noises that caught disrupt marine species.

Hydro-acoustic monitoring and the marine mammal monitoring program

Woodfibre LNG has worked closely with Squamish Nation’s environmental team to develop and implement the marine mammal monitoring program.

Construction activities that generate underwater noise require continuous underwater noise monitoring with hydrophones located at various distances from the active work. Hydrophones are specialized underwater microphones that pick-up vibrations through water which has different acoustic properties than air.

Construction activities that generate noise also require the establishment of marine mammal exclusion zones of up to 1000 metres, depending on real-time underwater noise data and regulated thresholds for underwater noise. These zones are typically determined based on the distance at which underwater noise levels drop below thresholds known to significant disturbance to marine mammals.

The exclusion zones and hydrophones are monitored continuously by a sizable team of up to 40 trained staff of marine mammal observers, hydrophone experts, and qualified professionals, including environmental monitors and experts engaged in the Project on behalf of Squamish Nation. Teams undertaking active construction activities creating underwater noise are in direct radio contact with the marine mammal team. If marine mammals are observed approaching an exclusion zone, the construction team is warned to be ready to halt work, and the activities are immediately halted if a marine mammal enters an exclusion zone. Work remains stopped until the Project’s Qualified Environmental Professionals are satisfied that work can resume with the safety and protection of marine mammals in mind.

Commitment to Howe Sound

Woodfibre LNG understands the added responsibility it has in building its facility in Howe Sound and actively working to ensure impacts on the marine environment are mitigated. The water, and the life within it, have deep cultural significance to the Squamish Nation and other Indigenous Peoples. Through a thorough, data-driven approach to underwater noise management, Woodfibre LNG will continue to advance its marine construction work with respect and care for the marine ecosystem.