Net Zero

Woodfibre LNG’s Roadmap to Net Zero

Setting a new global standard to be the world’s first net zero LNG facility.

In March 2023, Woodfibre LNG announced its Net Zero Roadmap, outlining the steps to become the first LNG facility in the world to achieve net zero emissions.

Net zero means that the facility will avoid Greenhouse Gas (GHG) emissions where possible and offset any residual emissions through the use of carbon offsets and/or other technologies to capture carbon before it is released into the air.

Through the use of renewable hydroelectricity and other best-in-class technologies, the Woodfibre LNG facility will be among the lowest carbon intensive LNG facility in the world. The carbon intensity of the Woodfibre LNG facility will be approximately 0.04 tonnes of CO2e per tonne of LNG (tCO2e/tLNG), well below the B.C. regulatory benchmark of 0.16 tCO2e/tLNG (Net Zero Roadmap, Pg 13).

The Roadmap outlines how Woodfibre LNG will be a net zero facility by 2027 – 23 years ahead of government net zero regulation. It also commits the company to be net zero at site during construction, which is a unique commitment for industrial construction projects in Canada.

As part the Squamish National Environmental Assessment Agreement, Woodfibre LNG commits to several actions that will decrease GHG emissions and lower environmental impact of the facility.

Achieving Net Zero

Electric Drive Compressors

Best-in-Class Emission Reducing Technologies

Nature Based Offsets

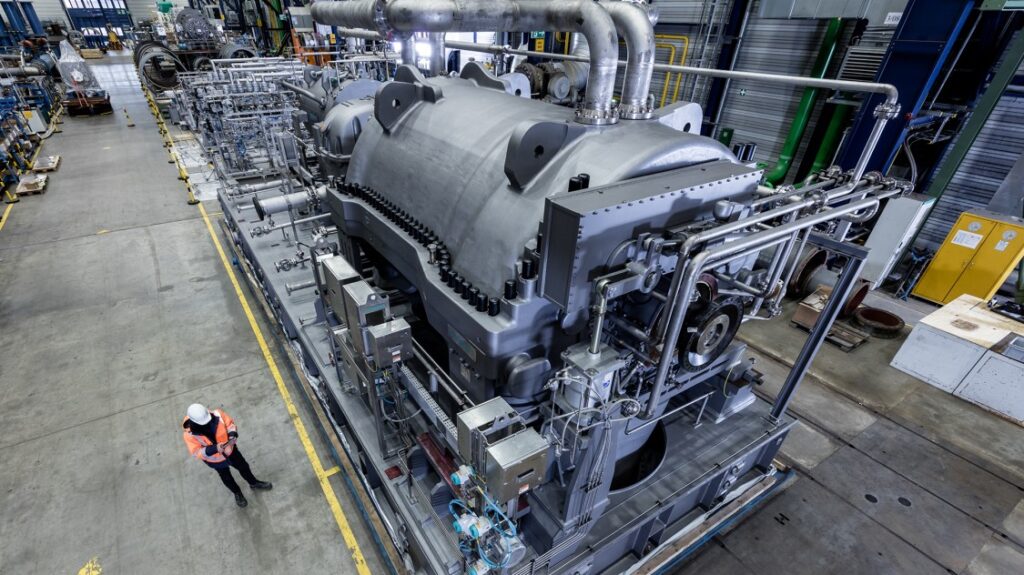

Electric Drive Compressors

The foundation of Woodfibre LNG’s approach to achieving Net Zero is the early decision to incorporate turbines powered by renewable hydroelectricity, rather than natural gas, to cool and liquify the feed gas. The E-Drive system delivers an emission intensity 14 times lower than conventional liquefaction facilities, resulting in stationary combustion emission reductions of approximately 230,470 tCO2e per year (Net Zero Roadmap, Pg 15).

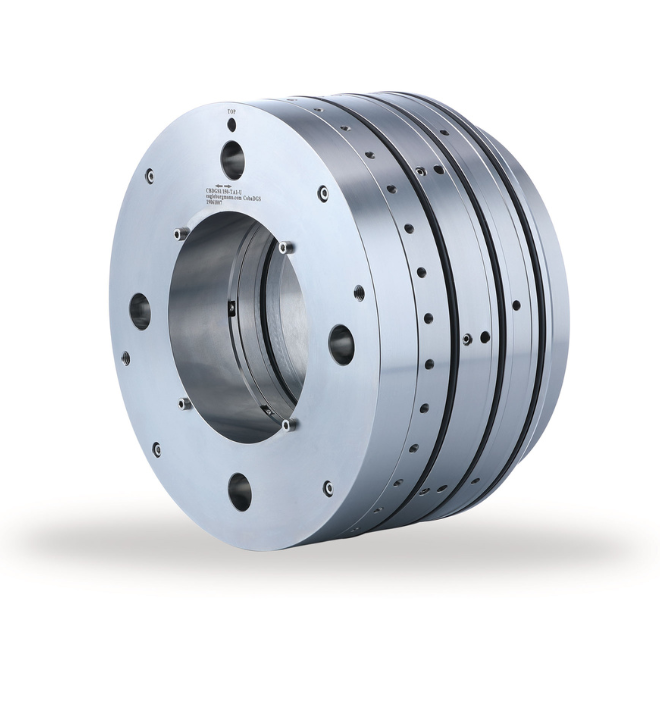

Best-in-Class Emission Reducing Technologies

The Woodfibre LNG Project has been designed to avoid or reduce emissions wherever possible. As part of the Squamish Nation Environmental Assessment Agreement process, we found ways to lower emissions and environmental impacts through the use of technologies, such as an air-cooling system, rather than a seawater cooling heat exchange system.

Other technologies include: High performance dry gas seals on the compressors to reduce emissions and enhanced Leak Detection and Repair surveys to detect and remedy any leaks as soon as they occur.

Woodfibre LNG continues to explore and pursue new opportunities to further drive down our GHG emissions. Part of the Net Zero Roadmap sets near, medium- and long-term opportunities to avoid emissions from the plant.

Nature Based Offsets

Woodfibre LNG is committed to reducing emissions wherever possible, and acknowledge that even the lowest carbon intensive LNG facilities have hard-to-abate emissions. To account for this, Woodfibre LNG purchases nature-based carbon credits from projects that have Indigenous partners and that that preserve large areas of B.C. forests to help sequester carbon from the atmosphere. While this does not replace the need to further reduce emissions, it does help ensure that the net emissions impact of the Woodfibre LNG project remains zero.