News & Insights

Towards Net Zero: Sustainability Meets Efficiency with E-Drive

Jun 3, 2025

In the first blog of this series, we introduced the roadmap that will make Woodfibre LNG one of the lowest-emission LNG facilities in the world. A key component of that strategy is the E-Drive system, an innovation that replaces traditional gas turbines with electric motor-driven compressors powered by electricity. In this article, we take a deeper dive into how E-Drives enhance efficiency, significantly reduce emissions, and outperform the conventional gas turbines that are commonplace in most LNG facilities around the world.

The Role of E-Drives in Sustainable LNG Production

At the heart of Woodfibre LNG’s low-emission design is its transition to an all-electric liquefaction process. Traditionally, LNG facilities rely on gas-fired turbines to drive their refrigeration compressors, which are responsible for the highest proportion of greenhouse gas (GHG) emissions in the production process. By replacing these turbines with electric motors, powered entirely by BC Hydro’s renewable hydroelectric grid, Woodfibre LNG achieves an emissions profile that is 14 times lower than conventional liquefaction processes.

The benefits of E-Drives extend beyond emissions reduction. These systems offer:

- Higher Energy Efficiency: Electric motors can convert over 95 per cent of electrical energy into usable power, making them far more efficient than gas turbines, which typically convert only about 60 per cent of energy into usable power. This leads to less energy waste and lower operational costs.

- Lower Maintenance Requirements: Unlike gas turbines, which may require 10 to 15 days of scheduled maintenance after three years of operation, electric motors can run for up to five years without major servicing, enhancing operational uptime and reliability.

- Operational Flexibility: With E-Drives, LNG plants can vary the speed of motors based on current needs, which helps optimize energy consumption and production efficiency. This flexibility allows the plant to respond to fluctuations in demand, maintain consistent performance, and reduce waste by only using the necessary amount of energy.

- Reduced Flaring: Flaring occurs when excess gas is burned off during processes upsets that require depressurizing or restarting. Suitably sized E-drives reduces the need for depressurizing, allowing for quicker restarts at settle-out pressures, resulting in less or even no flaring. This is something that is not feasible with single-shaft gas turbine-driven compressors, which require flaring in the depressurization process and a longer overall restart time.

Decarbonizing LNG production with Renewable Hydroelectricity

Electrifying LNG facilities is only half the equation as the source of electricity plays a crucial role in determining overall emissions. BC Hydro generates 98 per cent of its power from hydroelectric facilities from around the province and therefore has an extremely small GHG emission footprint. Woodfibre LNG’s strategic location in British Columbia allows it to tap into BC Hydro’s abundant supply of renewable power instead of generating their own power from natural gas on-site.

If a conventional LNG facility were to switch to E-Drives in a jurisdiction powered by coal or even lower-carbon gas-fired electricity generation, the emissions reduction would be more limited. The availability of hydroelectric power provides a definitive advantage for Woodfibre LNG for emissions reduction and reliability.

Overcoming Challenges in E-Drive Implementation

Choosing to use E-Drives does pose some technical challenges, particularly for facilities connected to an external power grid like Woodfibre LNG.

Maintaining voltage stability, managing harmonics (unwanted distortions in the electrical signal that can be caused by large motors), and ensuring seamless integration with the liquefaction process require advanced engineering solutions.

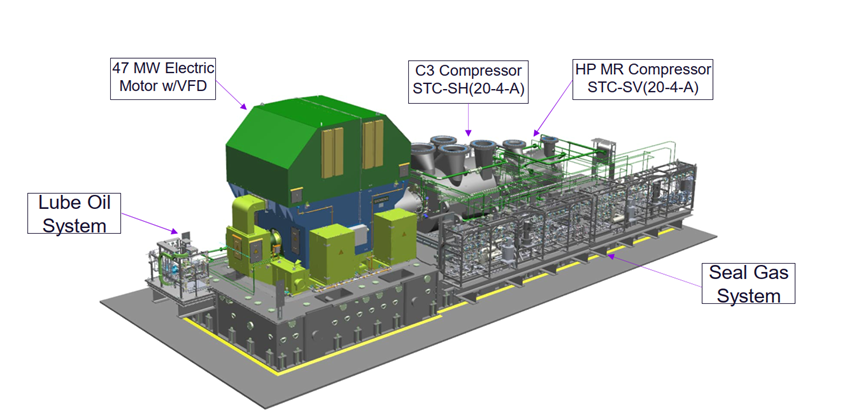

Woodfibre LNG has partnered with industry experts from Siemens Energy to create an improved electrical system that addresses challenges and boosts plant reliability and efficiency by using high efficiency synchronous motors, variable speed drives and harmonic filters.

A Blueprint for the Future of LNG

Woodfibre LNG’s commitment to E-Drive technology is more than just an operational choice – it’s a model for the future of lower-carbon LNG production. By combining cutting-edge efficiency with clean electricity integration, the use of E-Drives in the Woodfibre LNG facility demonstrates how the LNG industry can better support global climate goals while maintaining economic viability and improving reliability.

Stay tuned as we continue our “Towards Net Zero” series, exploring additional innovations that are making Woodfibre LNG the world’s first net-zero LNG export facility.